Ensuring your ice maker line is properly installed can significantly impact the efficiency and longevity of your ice maker. In Montgomery, OH, homeowners often overlook this aspect, focusing instead on the appliance itself. However, the route, materials, and placement of the shutoff valve play crucial roles. Understanding these elements can prevent leaks and ensure a steady supply of ice.

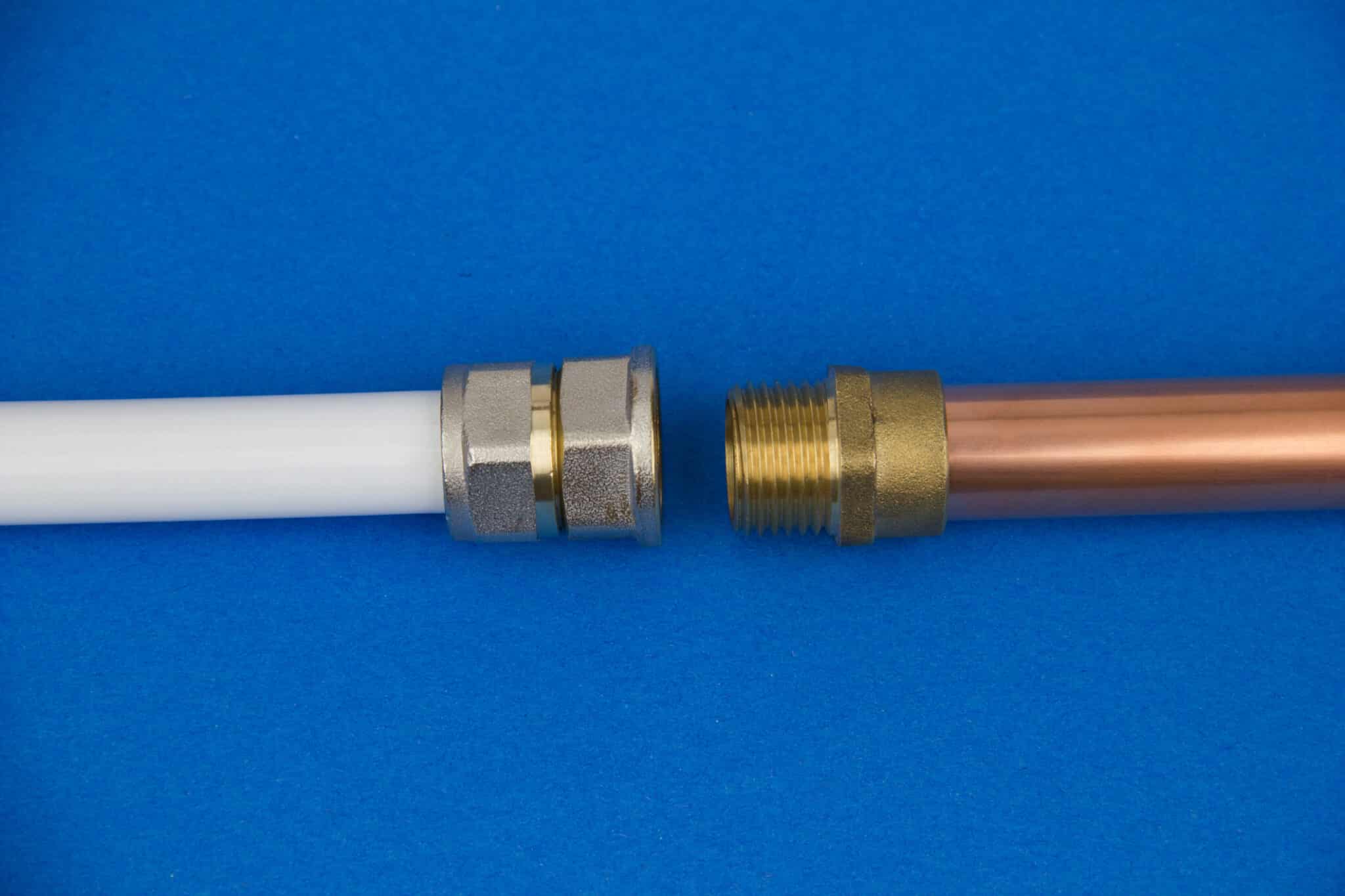

Choosing the right materials for your ice maker line is just as important as its placement. Flexible tubing, such as copper or stainless steel, is commonly recommended for its durability and resistance to kinks. In areas like Oakley, OH, where water conditions may vary, selecting the right material can also prevent corrosion. This choice helps maintain water quality and prevents unexpected maintenance issues.

The placement of the shutoff valve is another critical consideration. Ideally, it should be easily accessible for quick shutoff in case of a leak. This not only minimizes potential water damage but also simplifies routine maintenance. By strategically positioning the valve, homeowners can enjoy peace of mind, knowing they can quickly address any issues that arise.

Lastly, preventing leaks is paramount when installing or maintaining an ice maker line. Regular inspections and ensuring connections are secure can go a long way. In both Montgomery and Oakley, homeowners can benefit from professional advice on leak prevention strategies. By following these tips, you can enjoy uninterrupted ice production without the worry of water damage.

Choosing the Right Materials for Your Ice Maker Line

When selecting materials for your ice maker line, consider the water quality in Montgomery, OH. High mineral content can cause buildup in certain materials, leading to blockages or leaks. Copper tubing, known for its longevity and resistance to corrosion, makes an excellent choice. It ensures a clean water supply, reducing the risk of contamination.

In areas like Oakley, OH, where water conditions may differ, stainless steel tubing offers another robust option. Its flexibility and durability stand up well against various environmental factors. Stainless steel also resists kinks and bends, which can prevent water flow disruptions. This material choice guarantees a reliable ice maker line over the years.

For homeowners preferring an easier installation process, flexible plastic tubing presents a viable alternative. It’s lightweight and can be maneuvered through tight spaces without much hassle. However, it’s crucial to ensure the plastic is rated for potable water use and can withstand the pressure and temperature of the ice maker line. This way, you maintain both convenience and safety.

Regardless of the material chosen, installing a filter can significantly enhance the ice maker line’s performance. A filter helps remove impurities and minerals from the water before it reaches the ice maker. This not only improves the taste and clarity of the ice but also protects the line from potential damage caused by sediment buildup. Regularly replacing the filter as part of your maintenance routine will keep your ice production smooth and efficient.

The Importance of Proper Shutoff Valve Placement

Understanding the importance of proper shutoff valve placement for your ice maker line cannot be understated. In Montgomery, OH, where homeowners prioritize convenience and safety, having the shutoff valve in an accessible location is key. This ensures that in the event of a leak or when maintenance is required, the water supply can be quickly and easily stopped. Positioning the valve too far or in a hard-to-reach area can delay response times to leaks, increasing the risk of water damage.

When planning the installation of your ice maker line, consider the layout of your kitchen or utility area. In Oakley, OH, for example, it’s common to find the shutoff valve under the sink or behind the refrigerator. These locations offer easy access without requiring homeowners to move heavy appliances or reach into tight spaces. Remember, the goal is to combine practicality with efficiency, ensuring that the shutoff valve is both out of sight and within easy reach.

Regularly testing your shutoff valve is also crucial to ensure it’s working correctly. Just like any mechanical component, valves can wear out or become stuck over time. Homeowners should make it a habit to turn the valve on and off periodically to check its operation. This simple practice can prevent a minor issue from becoming a major problem, ensuring that when you need to shut off the water, the valve will function as expected.

Lastly, during installation, it’s wise to consult with a professional plumber who can advise on the best shutoff valve type and placement for your specific needs. They can offer insights into the most reliable brands and models that are suitable for the water conditions in your area. By taking this step, you not only ensure that your ice maker line is installed correctly but also that you have the best tools at your disposal for managing water flow and preventing leaks.

Preventing Leaks in Your Ice Maker Line Installation

Preventing leaks in your ice maker line installation begins with a meticulous approach to every detail. In Montgomery, OH, homeowners understand the importance of ensuring every connection is tight and secure. This attention to detail can significantly reduce the risk of leaks. By using the right tools and following the manufacturer’s instructions, you can create a reliable seal at every joint.

In Oakley, OH, it’s common practice to incorporate leak detection systems as a preventive measure. These systems can alert you to the presence of water where it shouldn’t be, allowing for quick action. Installing a leak detector near your ice maker line offers an extra layer of protection. It’s a smart investment that can save you from potential water damage and costly repairs.

Regular maintenance checks are also key to preventing leaks in your ice maker line. Over time, even the smallest of leaks can lead to significant issues. By inspecting your line annually, you can catch and address any signs of wear or damage early. This proactive approach not only keeps your ice maker running smoothly but also helps avoid water damage.

Lastly, understanding the common signs of a leak can help you act swiftly to mitigate any damage. If you notice unexplained water near your refrigerator or a drop in water pressure, it’s time to investigate. Early detection of these signs can lead to a quick resolution, preventing further damage to your home. Staying vigilant and informed about your ice maker line’s condition is the best defense against leaks.

Ice Maker Line Maintenance Tips

Maintaining your ice maker line in Montgomery, OH, involves more than just regular checks. It’s essential to clean the line periodically to prevent any buildup that can affect water quality and ice purity. Using a solution recommended by the manufacturer can help keep the line clear and free of contaminants. This practice ensures your ice maker operates efficiently, producing clean and clear ice.

In Oakley, OH, it’s crucial to be mindful of the ambient temperature around your ice maker line. Extreme cold can cause the water in the line to freeze, leading to potential cracks and leaks. Insulating your ice maker line can protect it from temperature fluctuations, preserving its integrity. This simple step can prevent unexpected disruptions in ice production and avoid costly repairs.

Another important maintenance tip is to replace any parts that show signs of wear or damage promptly. Components like the water filter or the line itself can degrade over time, impacting the performance of your ice maker. Regularly assessing these parts for any issues and replacing them when necessary can save you from bigger problems down the line. It’s a proactive approach to keeping your ice maker line in top condition.

Lastly, keeping an eye out for any changes in the performance of your ice maker can alert you to potential issues with the line. If you notice a decrease in ice production or changes in ice quality, it might be time for a closer inspection. Addressing these signs early can prevent more serious issues, ensuring your ice maker line continues to function as expected. This vigilance is key to enjoying uninterrupted service from your ice maker.

Troubleshooting Common Ice Maker Line Issues

Even the most carefully installed ice maker line can encounter issues, making troubleshooting a necessary skill for homeowners in Montgomery, OH. Common problems include blockages, which can reduce water flow or stop ice production altogether. Identifying these blockages early allows for quick resolution, ensuring your ice maker continues to function efficiently. Regularly flushing the line can help prevent these issues by removing any accumulated sediments.

Leaks are another frequent issue that can arise with ice maker lines, potentially leading to water damage in your home. In Oakley, OH, it’s important to inspect the line and connections for any signs of moisture or drips. If a leak is found, turning off the shutoff valve immediately can minimize damage. Then, tightening connections or replacing damaged sections of the line can often remedy the problem.

Sometimes, the ice maker may produce smaller or misshapen ice cubes, indicating a potential issue with the water supply. This could be due to low water pressure or a malfunctioning water inlet valve. Checking the water pressure and ensuring the valve is functioning properly can often resolve these issues, restoring normal ice production. It’s a simple check that can save a lot of frustration.

Lastly, if your ice maker stops working entirely, it’s crucial to check both the power supply and the ice maker line. A power issue could be at fault, or the line might be frozen, especially during the colder months in Montgomery, OH. Ensuring the ice maker is properly powered and gently thawing any frozen sections of the line can quickly bring your ice maker back to life. These troubleshooting tips can help maintain uninterrupted service and prevent costly repairs.

When to Call a Professional for Your Ice Maker Line

While DIY projects can be rewarding, there are times when calling a professional for your ice maker line is the best course of action. In Montgomery, OH, homeowners might face complex issues beyond their expertise, such as persistent leaks or blockages that simple troubleshooting can’t fix. A skilled plumber has the tools and knowledge to diagnose and resolve these problems efficiently. They ensure your ice maker line operates smoothly, preventing future issues.

In Oakley, OH, installing a new ice maker line or replacing an old one can be challenging without the right experience. Professionals understand local building codes and can ensure your installation meets all requirements. This not only guarantees your system’s reliability but also keeps you in compliance with local regulations. Opting for professional help can save you time and avoid potential headaches from incorrect installations.

Sometimes, the problem might not be with the ice maker line itself but with the connections to your home’s water supply. A professional can assess the entire system to identify any underlying issues that might not be immediately apparent. They can make necessary adjustments or repairs, ensuring your ice maker receives a consistent water supply. This comprehensive approach addresses the root cause, not just the symptoms.

Lastly, calling in a professional offers peace of mind, knowing that your ice maker line is in capable hands. They can provide valuable maintenance tips and suggest improvements to enhance your system’s longevity. Residents of Montgomery and Oakley, OH, can benefit from the expertise of a professional, ensuring their ice maker line remains functional and efficient for years to come.

Enhancing Efficiency: Insulating Your Ice Maker Line

Insulating your ice maker line can significantly improve its efficiency, especially in areas with varying temperatures like Montgomery, OH. By adding insulation, you reduce the risk of the water freezing within the line, which is crucial during colder months. This not only ensures a consistent supply of ice but also extends the lifespan of your ice maker line by protecting it from temperature-induced stress and cracks. Opting for proper insulation is a smart move for any homeowner looking to enhance their appliance’s performance and reliability.

In Oakley, OH, where temperature fluctuations can also be a concern, insulating your ice maker line offers an additional benefit of energy savings. When your line is well insulated, it helps maintain the water temperature, reducing the amount of work your ice maker has to do to freeze the water. This can lead to lower energy consumption and, consequently, lower utility bills. It’s an eco-friendly step that supports both your wallet and the environment.

Applying insulation to your ice maker line is a straightforward process that can often be done without professional help. You’ll need to choose the right type of insulation material that’s designed for water lines and can withstand the conditions in your home. Wrapping the line securely, without leaving gaps, ensures maximum efficiency. This DIY project is a cost-effective way to improve your ice maker line’s performance and prevent potential issues down the line.

Finally, regular checks on your insulated ice maker line are important to ensure it remains in good condition. Over time, insulation can degrade or become damaged, which could diminish its effectiveness. By inspecting the insulation periodically, you can catch and address any problems early, maintaining the efficiency of your ice maker line. This proactive approach keeps your ice maker running smoothly, providing you with a steady supply of ice without unnecessary hassle.

Frequently Asked Questions

How do you install an ice maker line?

To install an ice maker line, first, choose a flexible tubing material for easy routing. Ensure the tubing runs from the water supply to the fridge without kinks. Next, install a shutoff valve under the sink for easy access. Finally, check connections for leaks to prevent water damage.

What is the best shutoff valve for an ice maker?

The best shutoff valve for an ice maker line is a quarter-turn ball valve. These valves offer reliable performance and easy operation. They ensure a tight seal, reducing the risk of leaks. Opting for this type will make maintenance and repairs simpler.

Where should the ice maker line be routed?

Routing the ice maker line properly is crucial for efficient operation and leak prevention. Ideally, it should travel along a path that avoids sharp bends and heat sources. Placing it behind cabinets or through the basement can offer a clean, unobtrusive look. Ensure the route also allows for easy access to the shutoff valve for quick maintenance.

Can you use any pipe for the ice maker line?

Not all pipes are suitable for an ice maker line. It’s best to choose materials designed for potable water, like copper or PVC. These ensure safety and durability. Avoid using materials that can corrode or impart a taste to the water.

How often should the ice maker line be replaced?

It’s wise to replace the ice maker line every 5 to 7 years to prevent leaks and maintain water quality. Over time, even the best materials can degrade or become damaged. Regular inspection can help identify when it’s time for a replacement. This proactive approach ensures your appliance continues to operate efficiently and safely.